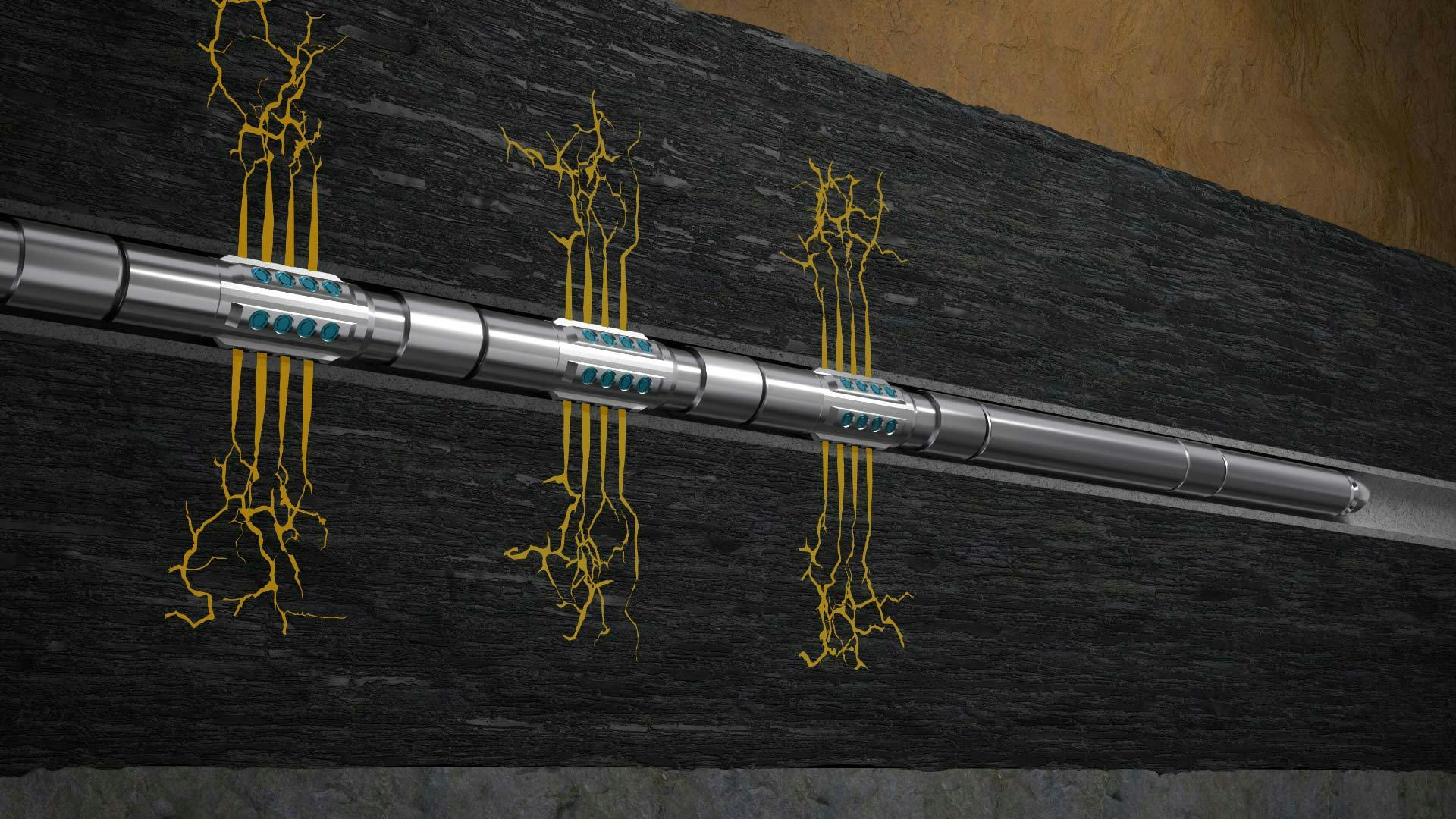

We proposed the BPS™ Maxx, which is designed for use in horizontal completions to establish fluid injection at the toe without intervention, as a solution. This feature eliminates the need for intervention using traditional tubing-conveyed perforating guns as a means of gaining access to the formation at the toe. Once activated, the high flow area of the BPS Maxx allows greater injection rates to support plug-and-perf or frac sleeve operations.

The BPS Maxx uses the same field-proven technology previously used in over 20,000 successful installations but with approximately three times greater flow area of our standard offering. Larger flow areas mean less risk in plugging from debris left in the well after cementing operations, and full ID through the tools eliminates the need for special wiper plugs, thereby reducing operational risks. On the well, three BPS Maxx units were installed with two casing joints in between to create the first frac stage cluster, eliminating toe initiation and pre-prep work.

In this more productive reservoir contact area, the operator achieved a stimulation rate of 96 bbl/min at a max surface treating pressure of 8,800 psi. The ability to eliminate the toe initiation stage provided the operator more productive reservoir contact area. It also allowed the operator to downsize the shoe track length to the minimum, clean the wellbore from any cement stringers after stimulating the first stage, and eliminate the risk associated with plug-and-perf operations on the first stage.