IntelliServ

Transfer data instantaneously from downhole to surface.

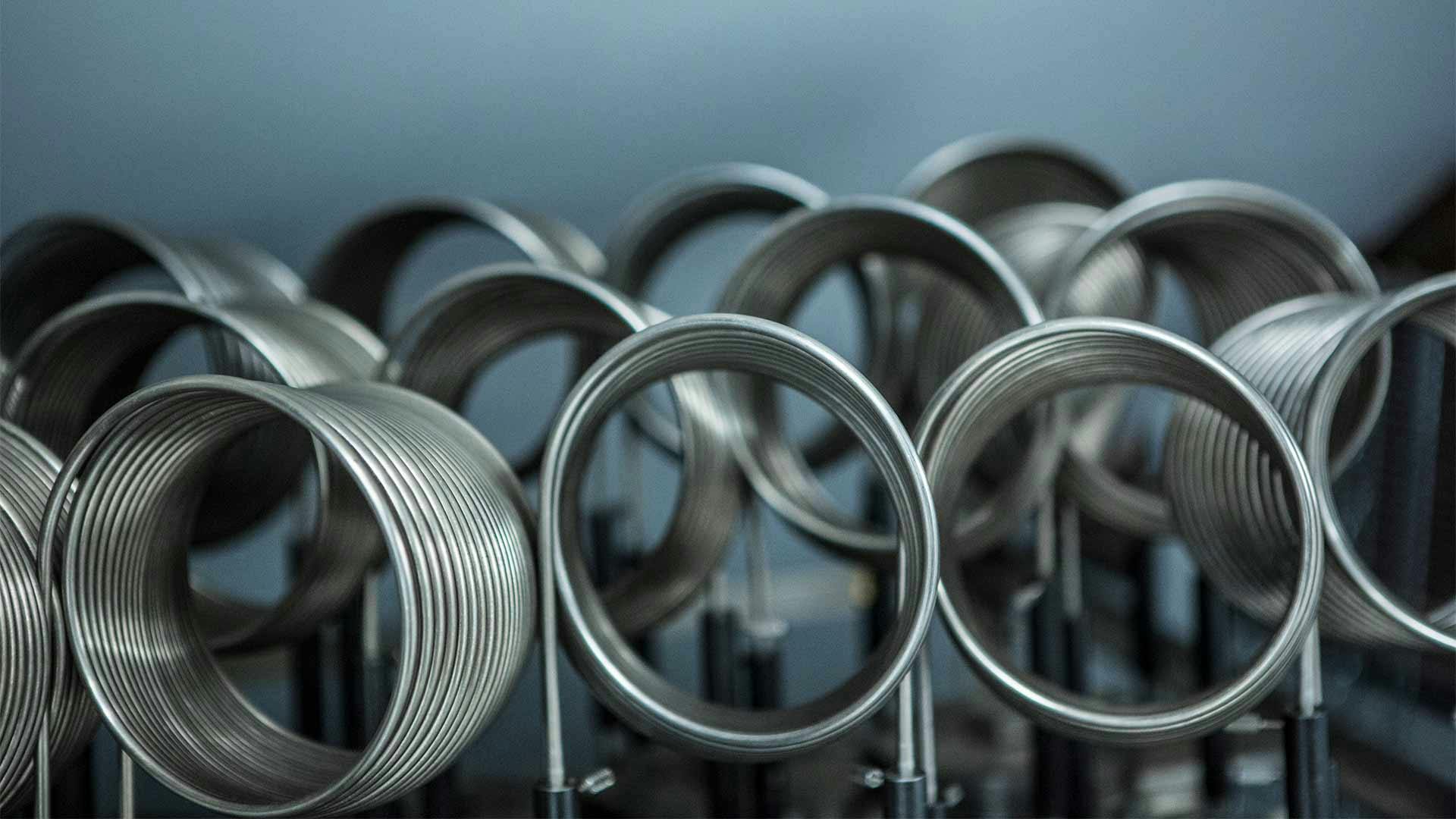

Wired Drill Pipe

IntelliServ Wired Drill Pipe enables instantaneous and bi-directional transmission of downhole data while drilling. Rig time is saved as data-driven activities are performed in a manner of seconds versus minutes with conventional telemetry. Performance limiters associated with LWD data density, directional control, well placement and hole cleaning management can be addressed with high frequency and low latency data, enabling higher rates of penetration (ROP) to be achieved. By transmitting the same data required to drill a well, simply faster, well times can be reduced by multiple days.

Net Cost Savings

In many drilling campaigns, using IntelliServ with select optimization applications and downhole tools eliminates significant time from the campaign. These days-per-well reductions can exceed the cost of wired drill pipe, delivering net cost savings per well. Download the PDF, which contains information on potential business case frontiers for IntelliServ use, for additional information.

For drilling operations, understanding downhole conditions is key. In addition to advanced modeling of downhole conditions, high-speed telemetry and wired drill pipe enable us to monitor downhole data in real time, which was not available before. Our goal for the future is to act upon real-time downhole data to improve drilling efficiency and to avoid problems related to downhole conditions. Also, high-speed telemetry will potentially improve placement of our wells in the reservoirs.

Statoil